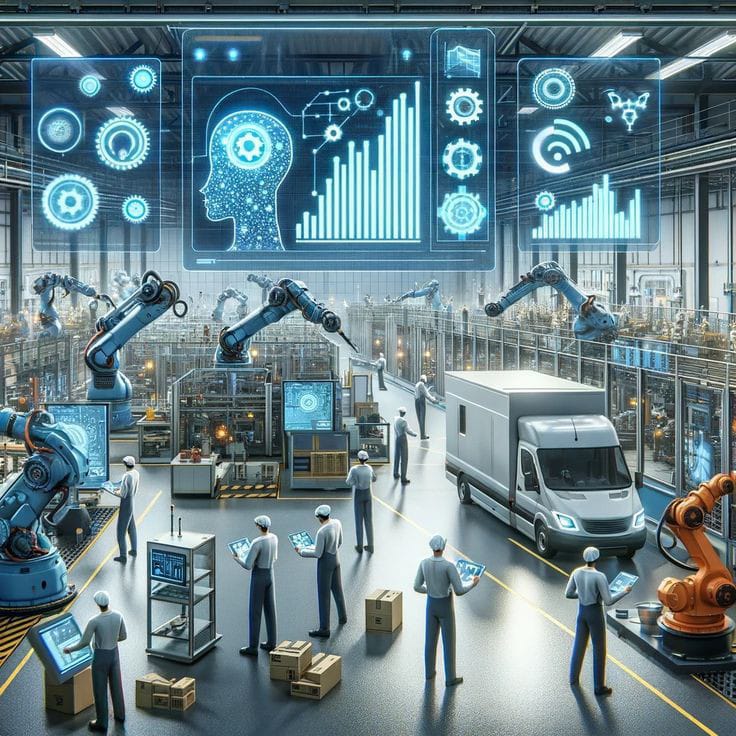

Innovative Automation Solution

Delivering Tailored Solutions for Enhanced Industrial Performance - Enhancing Efficiency, Precision, and Productivity Across Industries

We offer advanced machine vision solutions to enhance quality control and operational efficiency in manufacturing. Our systems provide precise inspection, measurement, and identification to ensure high standards and reduced downtime.

Our robotics solutions deliver cutting-edge automation for various industries, improving productivity and reducing manual labor. We integrate robotic arms, AGVs, and collaborative robots to streamline complex processes and boost efficiency.

We specialize in designing and implementing bespoke automation solutions tailored to your unique operational needs. Our customized systems optimize workflows, increase production rates, and provide scalable automation for future growth.

With vast experience in various industries water, mining, solar, semicon, automotive, pharma, packaging etc. we provide EPC solution for all your automation and instrumentation need. Our team is equipeed to deliver IOT based solution for customers to achieve there digital transformation goals.

We provide water and waster water projects related Automation and Instrumentation solutions including analyzes and special instruments. We are turnkey service provider for all your automation need.

Provide solution for both the solar and semiconductor industries rely on advanced technologies and precision engineering to enhance efficiency, performance, and sustainability in energy generation and electronic components.